Sustainable & Weather-proof Cladding Solutions

Sustainable

The selection of cladding materials is not just about safety and functionality, but also about future. Like many industries today, the architectural cladding section is faced with countless environmental challenges, including the impact on climate change, sustainability of materials, and methods of waste disposal.

At Futural, our commitment to a sustainable future is one of core values - we understand the particular environmental responsibilities inherent in our industry and concentrate on products that provide long life performance, low maintenance requirement and 100% recyclability, contributing to reducing the overall environmental footprint of the building.

Futural is 3mm solid aluminium cladding panels manufactured from more than 30% recycled material and is 100% recyclable again. Featuring 5000 marine grade alloy and highly-durable PVDF coatings, Futural has a long-lasting service time whilst only needs minimal maintenance for aesthetic reasons, hence an ecological life-cycle.

Futural was coated in a continuous process before the aluminium is fabricated into panels, minimising the need for additional transportation compared to powder coating process.

The coating process is a highly efficient 'closed loop' process burning the harmful VOCs and use them as fuel, therefore saving energy and eliminating pollutants.

Futural plays a key role in the sustainability of new buildings and the renovation of existing ones. Its high performance contributes to better energy efficiency, greater safety and enhanced comfort of buildings.

Weather-Proof

A key focus in today’s UK building industry, weatherproofing refers to the process of making a building capable of withstanding the effects of weather without damage.

Weather-proof cladding solutions helps avoid undue dampness and deterioration of building elements preventing unhealthy or dangerous conditions developing inside the building that could affect the well being of occupants.

With the rising cost of materials, weather-proof cladding solutions don't just minimise the chance of potential problems occurring after the completion of construction but also keep maintenance costs down for years to come. At Futural, our cladding products and systems are stringently manufactured and tested to be completely corrosion-resistant, wind-resistant, high impact-resistant and breathable.

![]() Futural is 3mm solid aluminium manufactured from 5000 marine grade alloy. lt has an

ultimate tensile load up to 215MPa and a surface hardness up to 70HV5.

Futural is 3mm solid aluminium manufactured from 5000 marine grade alloy. lt has an

ultimate tensile load up to 215MPa and a surface hardness up to 70HV5.

![]() Futural only uses highly durable PVDF coating system and has passed massive durability testings,

including chemical solvent resistance, impact resistance, abrasion resistance,

and 4000 hours accelerated weathering tests.

Futural only uses highly durable PVDF coating system and has passed massive durability testings,

including chemical solvent resistance, impact resistance, abrasion resistance,

and 4000 hours accelerated weathering tests.

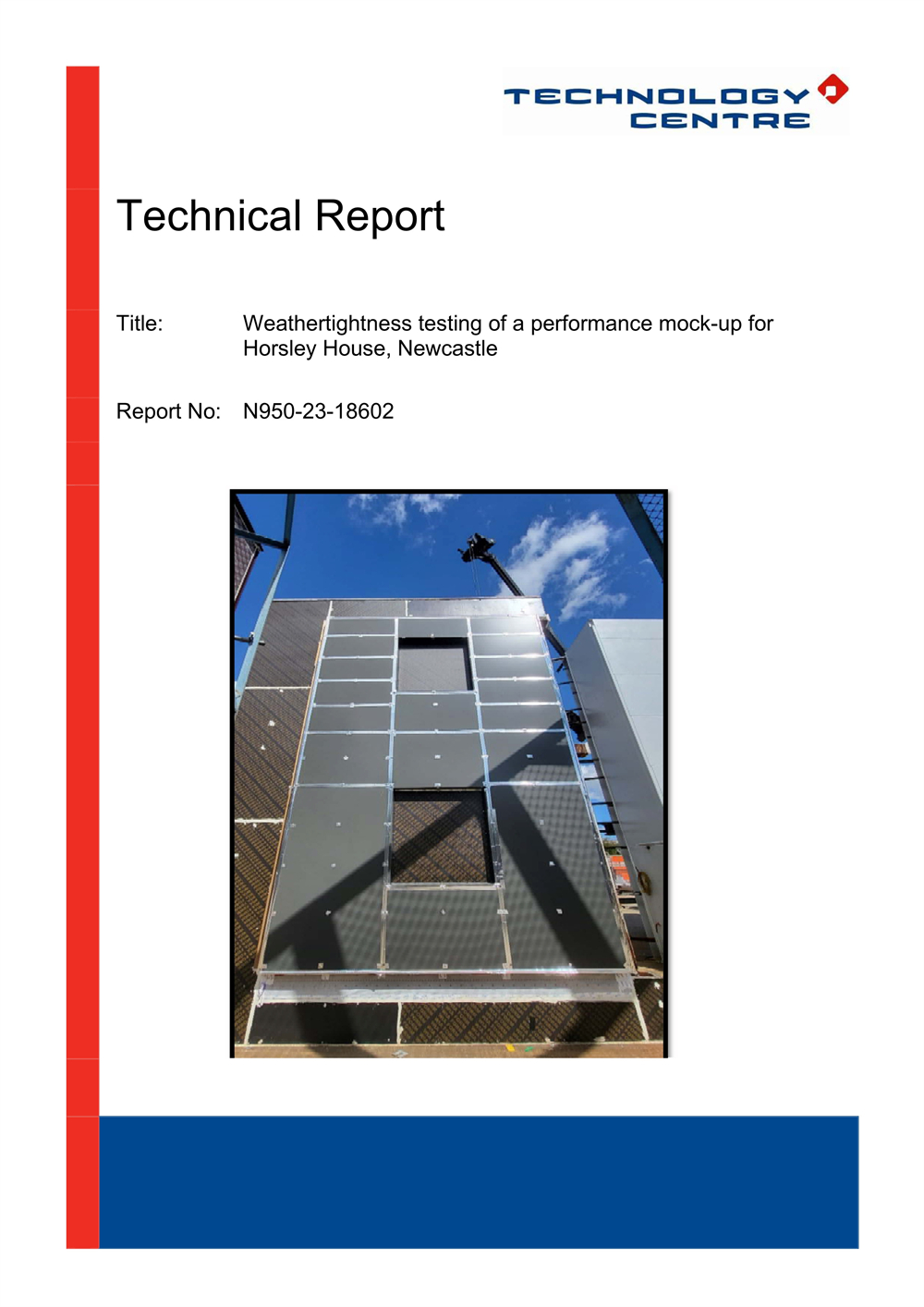

![]() Futural has been tested to be compliant with CWCT standards,

including air permeability testing, watertightness testing, wind resistance testing,

and impact resistance testing.

Futural has been tested to be compliant with CWCT standards,

including air permeability testing, watertightness testing, wind resistance testing,

and impact resistance testing.

![]() Futural cladding systems offer various versatile fixing options that have been tested to CWCT standards.

Futural cladding systems offer various versatile fixing options that have been tested to CWCT standards.

Coating system

4000 hours Accelerated Weathering Tested

Futural uses PVDF coating system, known for its high durability and superior weather resistance. Futural has been stringently tested to be compliant with the AAMA2605 and EN 1396 standard, including 4000hrs salt spray, 4000hrs humidity, 2000hrs UV, and 1000hrs Acetic accelerated weathering tests. Its superior coating durability and marine grade aluminium ensure that the fascinating facades of your buildings can last for decades even under high pollution and corrosion circumstances.

| 4000 hours Salt Spray Accelerated Weathering Test | Download Test Report |

| 4000 hours Humidity Accelerated Weathering Test | Download Test Report |

| 2000 hours UV Accelerated Weathering Test | Download Test Report |

| 1000 hours Acetic Salt Spray Accelerated Weathering Test | Download Test Report |

| AAMA 2605 Coating Properties Tests | Download Test Report |

Looking To Use Futural

For Your

Next Project?