QUALICOAT & AAMA STANDARDS

What is Qualicoat Standard?

Formed by several national associations in 1986, Qulicoat is an organization committed to maintaining the quality of coating on aluminium and its alloys for architectural applications. It has established Specifications defining minimum requirements for plant and equipment, coating materials and finished products, also known as Qualicoat Standards.

The standards set out specific testing and assessing methods on the coating of coated aluminium products. Based on the testing, products can be classified into 3 classes:

- Class 1 Standard durable

- Class 2 High durable

- Class 3 Super durable

What is AAMA Standard?

AAMA, abbreviation for American Architectural Manufacturer’s Association (now incorporated into FGIA), was founded in 1936 to become a leader in producing performance standards, product certification and educational programs for the architectural industry. It developed 3 standards by which architects and designers can easily identify the differences between coating performance on aluminium:

- AAMA 2603 Good performance

- AAMA 2604 High performance

- AAMA 2605 Superior performance

Differences between Qualicoat & AAMA

- Areas – Qulicoat is more popular in Europe whilst AAMA is more used in the rest of the world, such as America, Asia, Australia, and Middle East.

- Coating Types – Qulicoat is mainly used on PPC (polyester powder coated) panels featuring a post-coating process whilst AAMA is mainly used on PVDF(Polyvinylidene fluoride) panels featuring a coil-coating process.

- Testing Standards – Qulicoat mainly uses European standards whilst AAMA uses American standards

Common ground between Qualicoat & AAMA

- Applications – Both standards are used to identify the coating performance on aluminium

- Compositions – Both standards have 3 levels of performance

- Coating Properties to be assessed – Although Qualicoat and AAMA use different testing standards, some of the methods are equivalent or even the same. Most importantly, the properties of the coating to be assessed by both standards are almost identical.

See summary as follows:

| Testing ltems |

|

|

| Coating Thickness & Gloss | ||

| Coating Adhesion | ||

| Coating Abrasion Resistance | ||

| Coating Chemical Reistance | ||

| Coating lmpact Resistance | ||

| Accelerated Weathering test | 1000hrs Filiform Corrossion Test | 4000hrs Humidity Resistance Test |

| 2000hrs Acetic Acid Salt Spray Test | 4000hrs Netural Salt Spray Test | |

| Natural Weathering test | 10-year South Florida Exposure Test | 10-year South Florida Exposure Test |

| Gloss Retention > 50% | Gloss Retention > 50% |

Summary

Qualicoat Class 3 and AAMA 2605 are both known as “10-year Florida” coating. Qualicoat Class 3 is widely used on PPC aluminium panels in Europe, whilst AAMA 2605 is more applicable to PVDF pre-coated aluminium in the rest of the world. Both standards are at the same high level where most demanding tests and assessments are required, representing the authoritative specifications for aluminium with superior coating performance.

Coating system

4000 hours Accelerated Weathering Tested

Futural uses PVDF coating system, known for its high durability and superior weather resistance. Futural has been stringently tested to be compliant with the AAMA2605 and EN 1396 standard, including 4000hrs salt spray, 4000hrs humidity, 2000hrs UV, and 1000hrs Acetic accelerated weathering tests. Its superior coating durability and marine grade aluminium ensure that the fascinating facades of your buildings can last for decades even under high pollution and corrosion circumstances.

| 4000 hours Salt Spray Accelerated Weathering Test | Download Test Report |

| 4000 hours Humidity Accelerated Weathering Test | Download Test Report |

| 2000 hours UV Accelerated Weathering Test | Download Test Report |

| 1000 hours Acetic Salt Spray Accelerated Weathering Test | Download Test Report |

| AAMA 2605 Coating Properties Tests | Download Test Report |

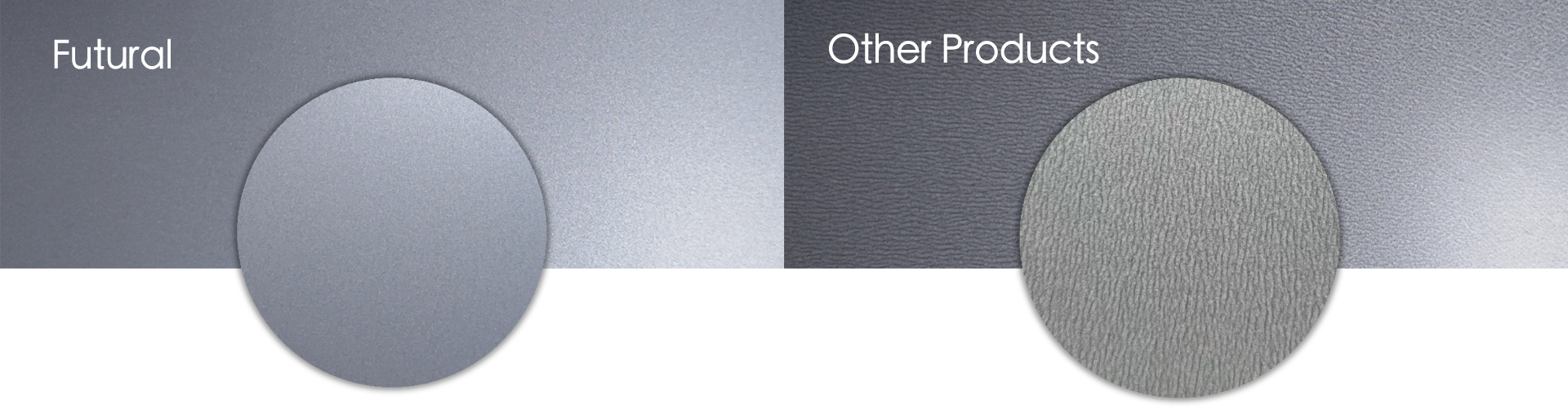

Delicate Coating Surface

Futural has delicate coatings without "Orange Peels Patterns" that often appear on PPC panels and other similar products, featuring an absolutely exquisite and aesthetically-pleasing appearance.

Long with excellent durability another advantage of PVDF coating is the maintenance of panels is simpler, faster and more efficient than PPC alternatives. PVDF also outperforms traditional post paint methods when it comes to external weather durability due to better tolerance of heat, oxidation and Humidity.

Looking To Use Futural

For Your

Next Project?