Futural

Non-combustible Cladding Systems

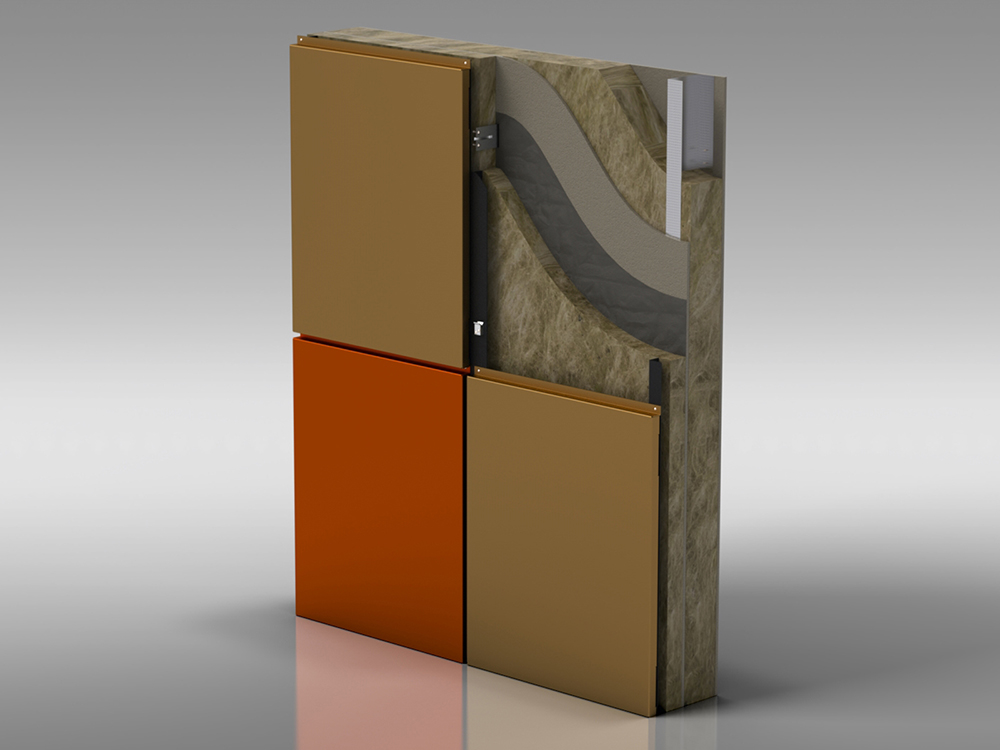

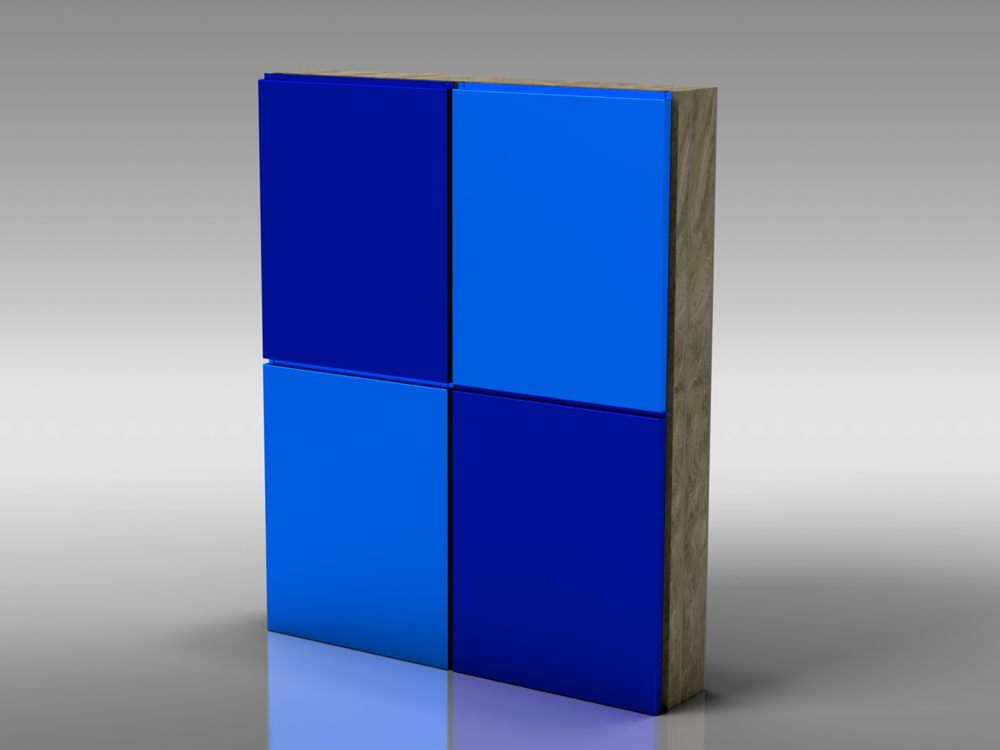

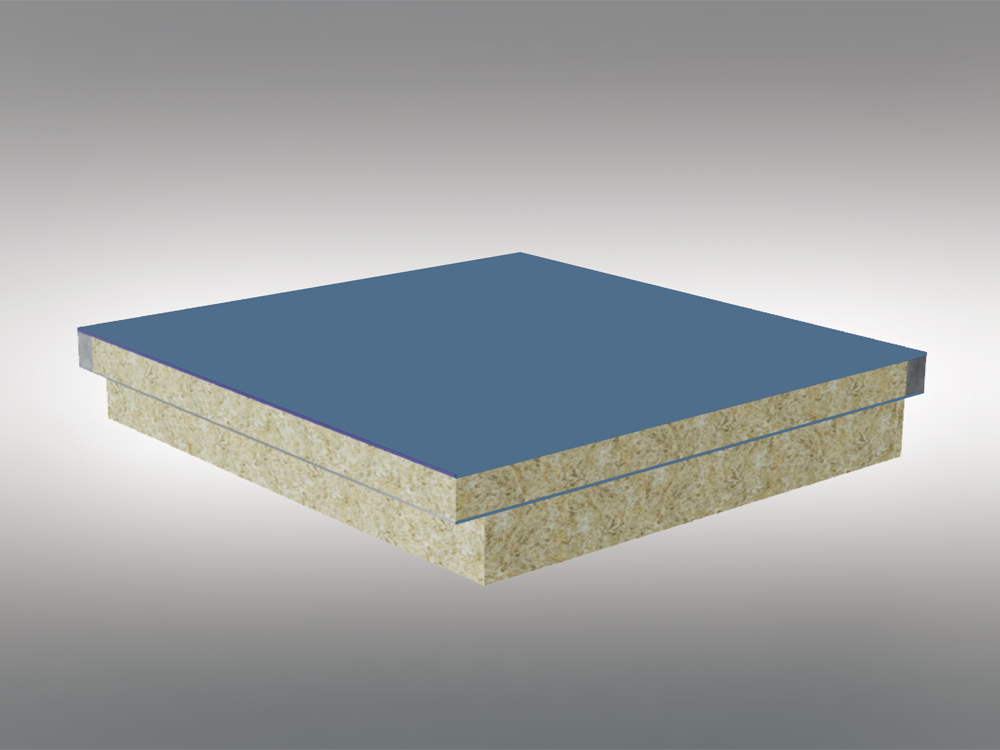

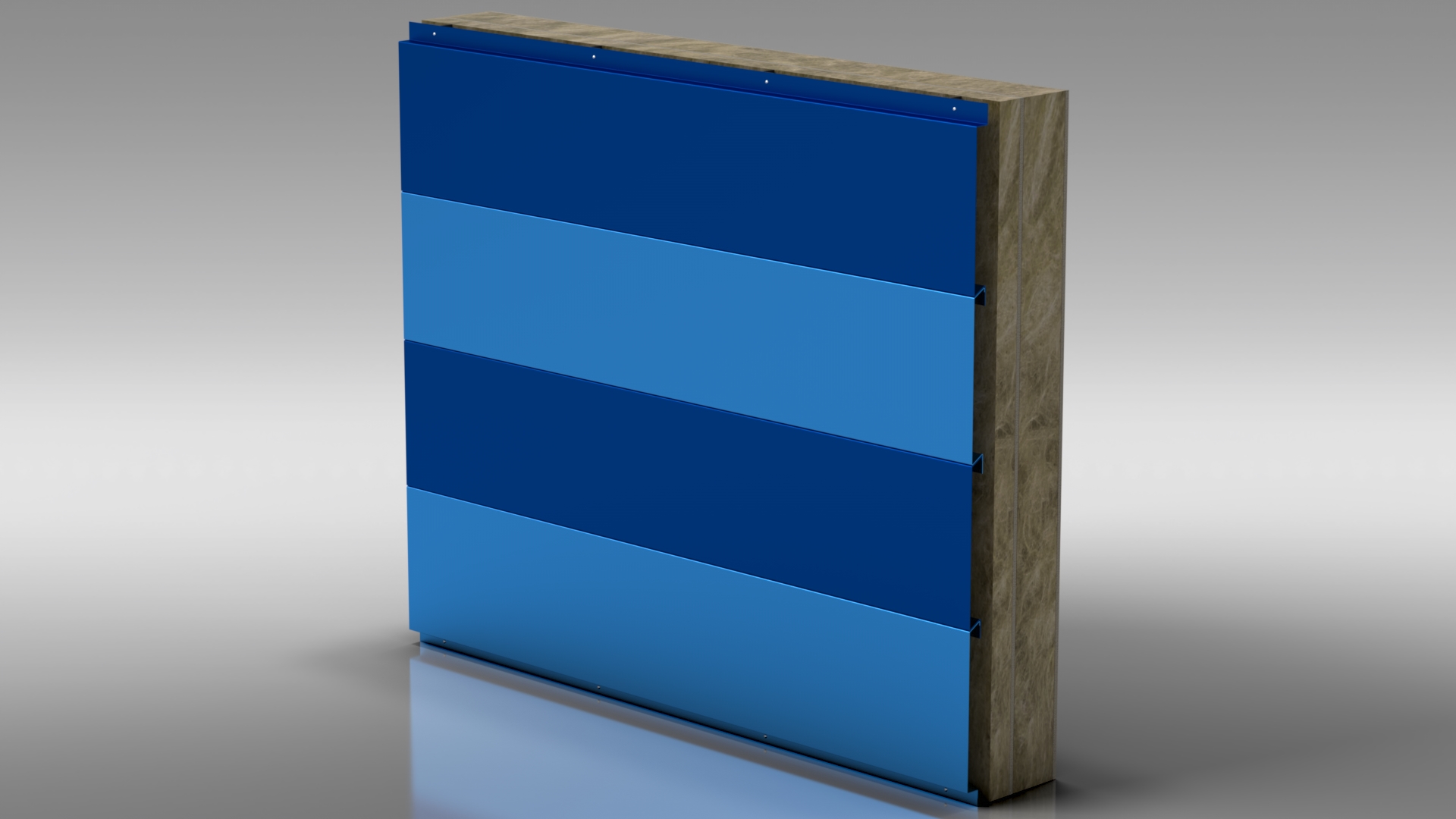

Futural Cladding Systems, comprising of only A1/A2 elements and tested to CWCT standards, provide a complete facade solution with superior thermal and acoustic performance, impact and fire resistance, as well as outstanding weatherproofing. Available in various fixing types, it creates versatile design possibilities whilst completely meeting all UK regulations and almost all design requirements.

Benefits

NON-COMBUSTIBLE

NON-COMBUSTIBLE

All system components are A1/A2 Non-combustible

COMPLETE COMPLIANCE WITH UK REGULATIONS

COMPLETE COMPLIANCE WITH UK REGULATIONS

Meeting all UK Regulations including Building Regulations 2010, Construction Product Regulations 2011, and Building Safety Act 2022

TESTED TO CWCT STANDARDS

TESTED TO CWCT STANDARDS

Offering a superior weatherproofing performance

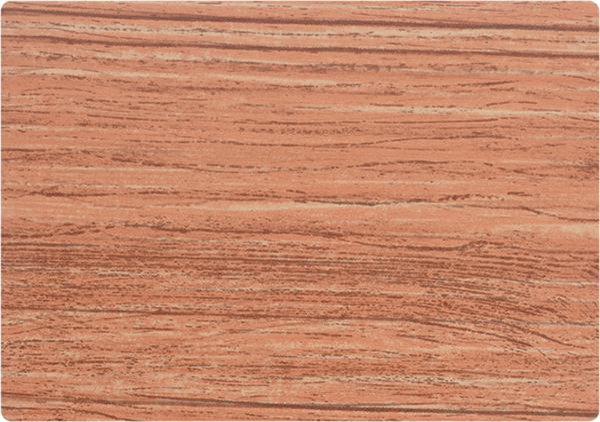

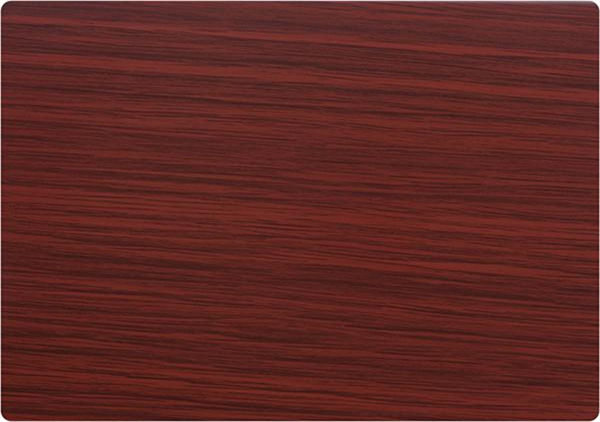

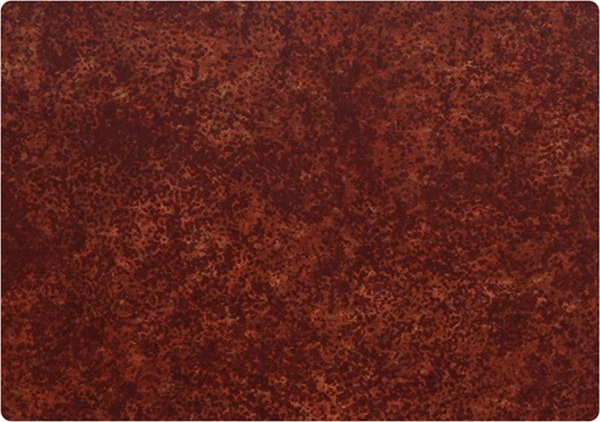

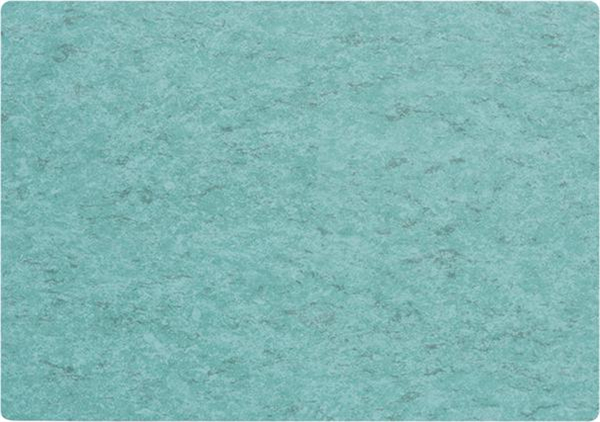

VARIOUS FIXING OPTIONS AND COLOUR SELECTIONS

VARIOUS FIXING OPTIONS AND COLOUR SELECTIONS

Providing aesthetic appeal and versatility

ONE-STOP SOLUTIONS

ONE-STOP SOLUTIONS

All components come from the same integrated supply chain, contributing to significant cost and time savings.

COMPLETE WARRANTY & ASSURANCE

COMPLETE WARRANTY & ASSURANCE

Up to a 30 year whole system warranty

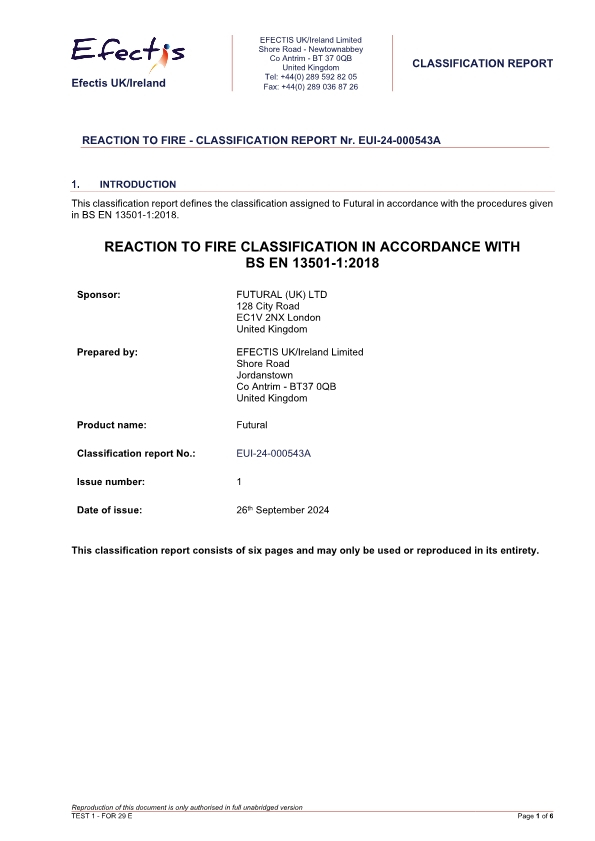

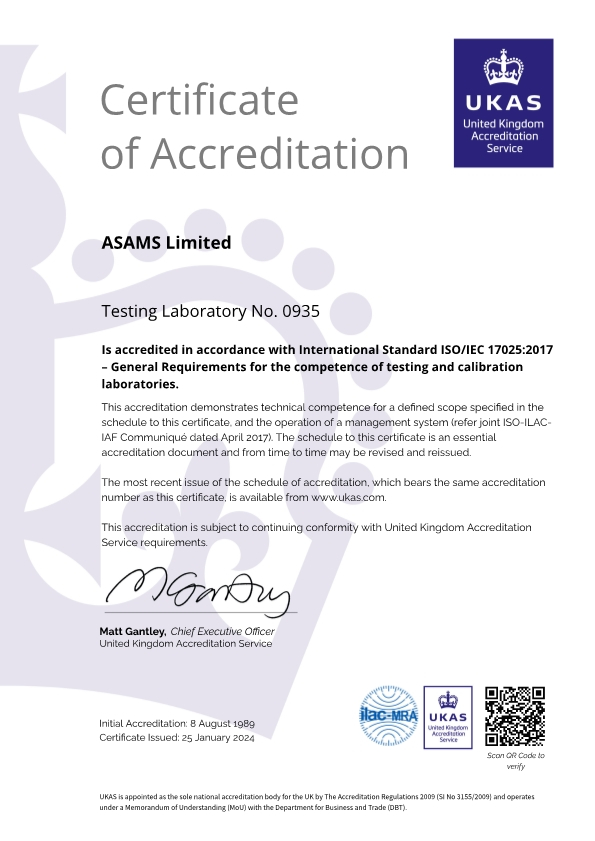

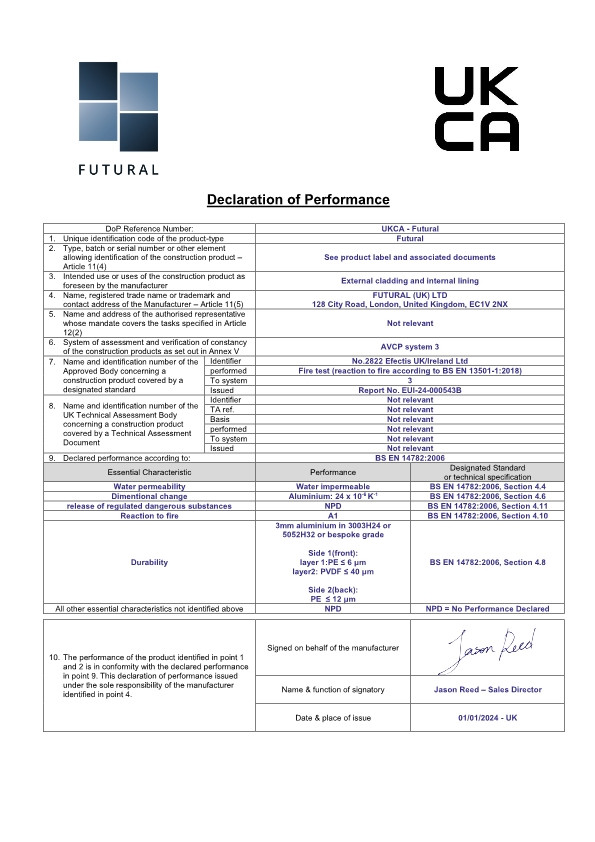

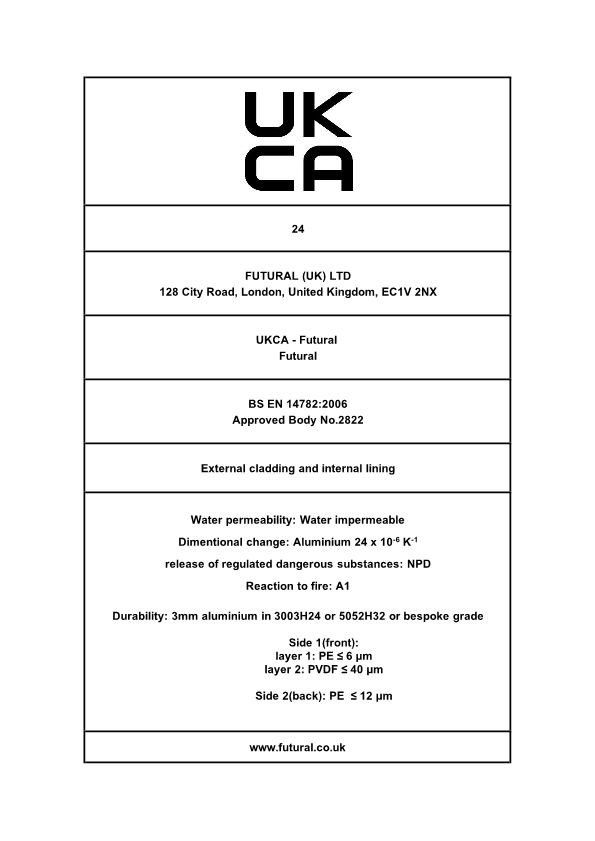

Futural has been UKCA marked & fully tested

100% Compliance with all UK Building Regulations

| Building Regulations 2011 | Compliant |

| Construction Products Regulations 2011 | Compliant |

| Building Safety Act 2022 | Compliant |

| CWCT standards | Compliant |

| UKCA | Compliant |

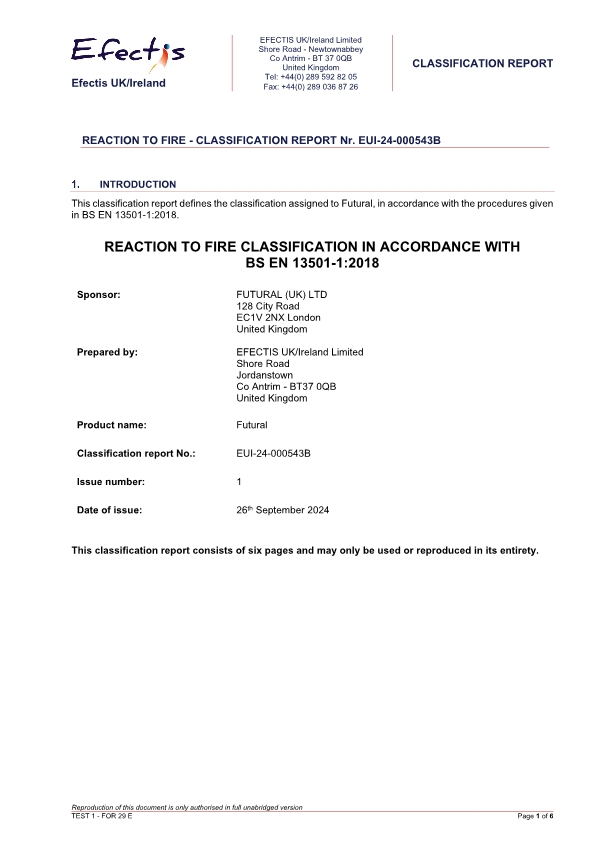

| Fire Rating | A1 to BS EN 13501-1 |

| Coating Properties | 4000 hours Humidity and 4000 hours Salt Spray tested |

| 2000 hours UV and 1000 hours Acetic Spray tested | |

| Compliant with AAMA 2605 and EN 1396 | |

| Tensile Properties | Compliant with EN 485-2 |

| Chemical Properties | Compliant with EN 573-3 |

Specifications

| Aluminium Grade | 3000 series or 5000 series |

| Standard Thickness | 2mm, 3mm |

| Standard Width | 1250 or 1500mm |

| Standard Length | 2500, 3200 or 4000mm |

| Tensile Strength | 145-260 MPa |

| Thermal Conductivity | 138 W/mK |

| Download Full Technical Data sheet >> | |

Coating system

4000 hours Accelerated Weathering Tested

Futural uses PVDF coating system, known for its high durability and superior weather resistance. Futural has been stringently tested to be compliant with the AAMA2605 and EN 1396 standard, including 4000hrs salt spray, 4000hrs humidity, 2000hrs UV, and 1000hrs Acetic accelerated weathering tests. Its superior coating durability and marine grade aluminium ensure that the fascinating facades of your buildings can last for decades even under high pollution and corrosion circumstances.

| 4000 hours Salt Spray Accelerated Weathering Test | Download Test Report |

| 4000 hours Humidity Accelerated Weathering Test | Download Test Report |

| 2000 hours UV Accelerated Weathering Test | Download Test Report |

| 1000 hours Acetic Salt Spray Accelerated Weathering Test | Download Test Report |

| AAMA 2605 Coating Properties Tests | Download Test Report |

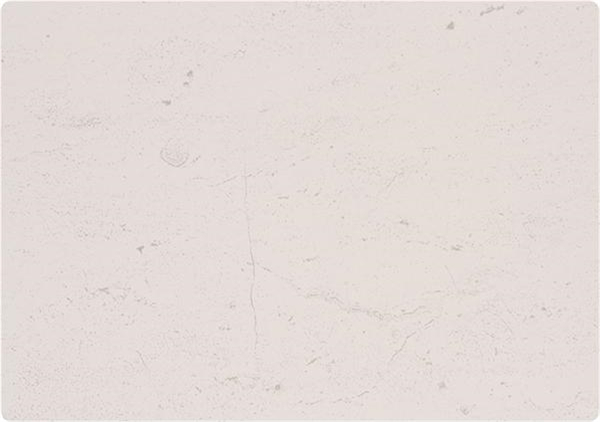

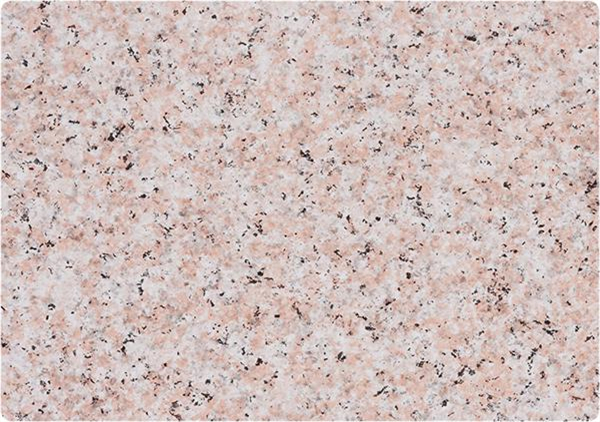

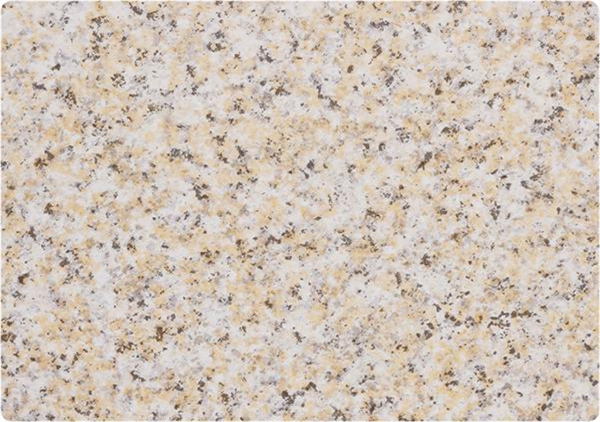

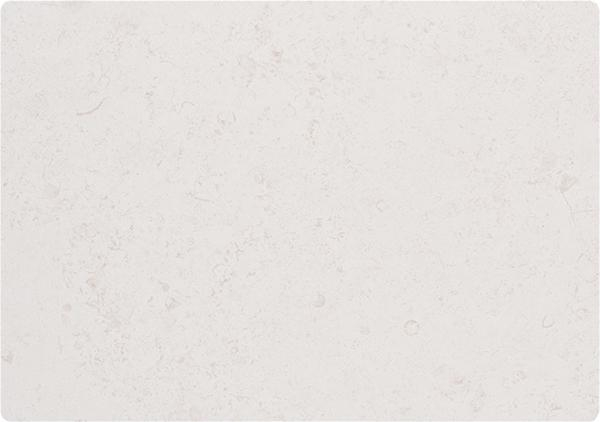

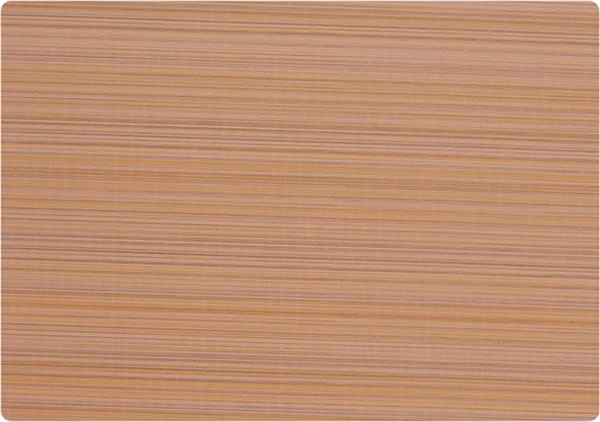

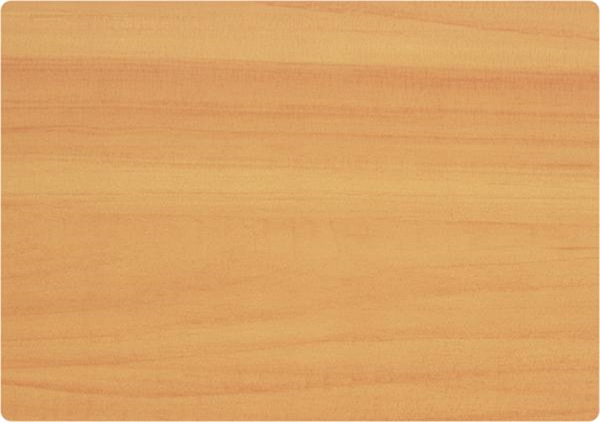

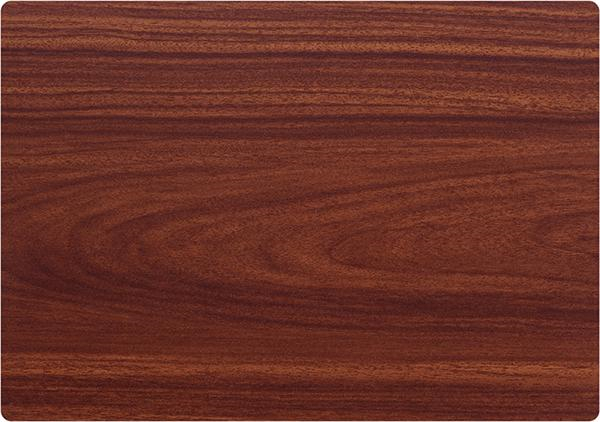

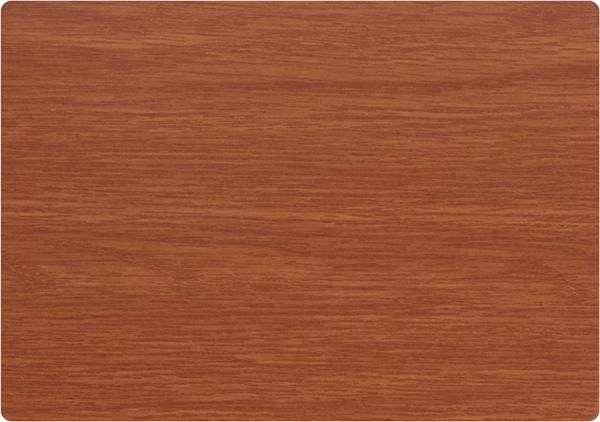

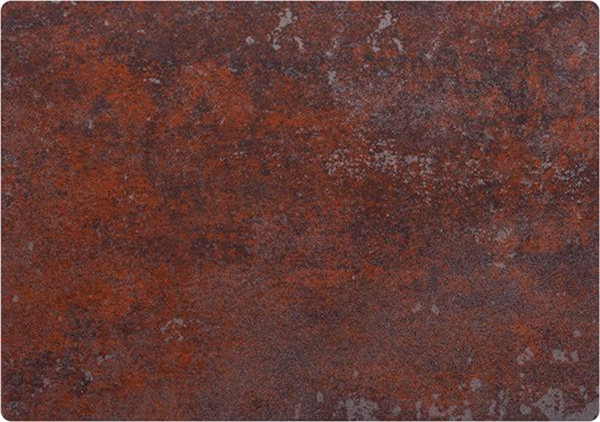

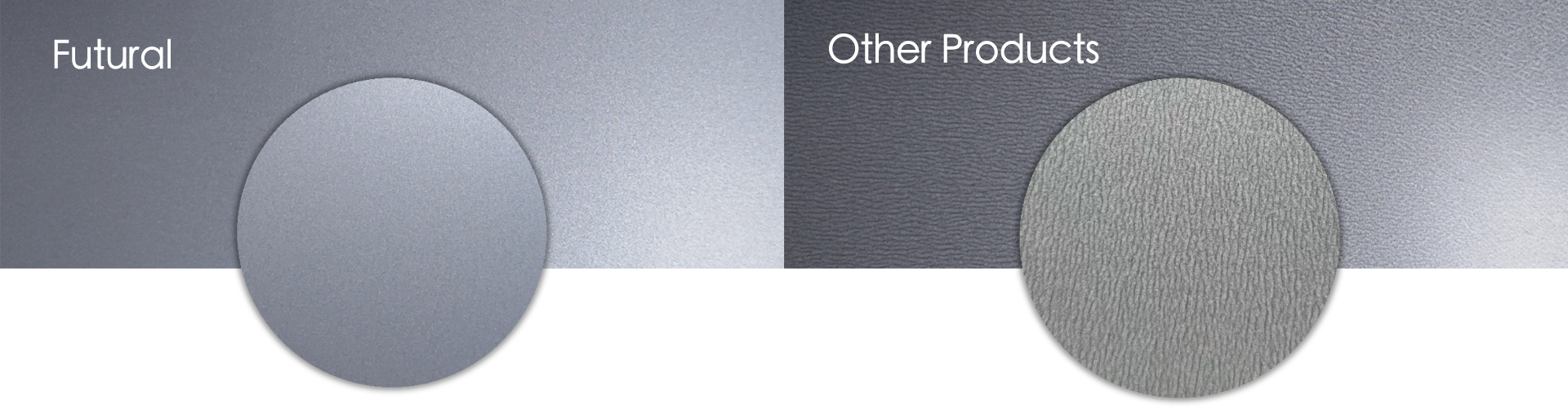

Delicate Coating Surface

Futural has delicate coatings without "Orange Peels Patterns" that often appear on PPC panels and other similar products, featuring an absolutely exquisite and aesthetically-pleasing appearance.

Long with excellent durability another advantage of PVDF coating is the maintenance of panels is simpler, faster and more efficient than PPC alternatives. PVDF also outperforms traditional post paint methods when it comes to external weather durability due to better tolerance of heat, oxidation and Humidity.

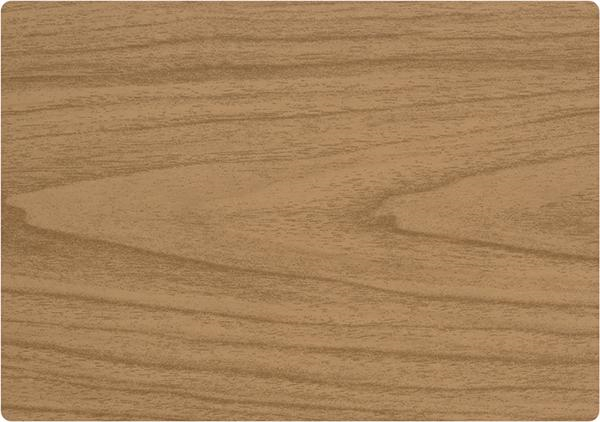

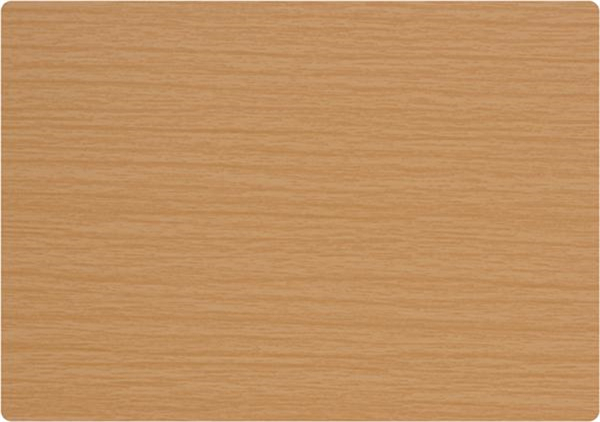

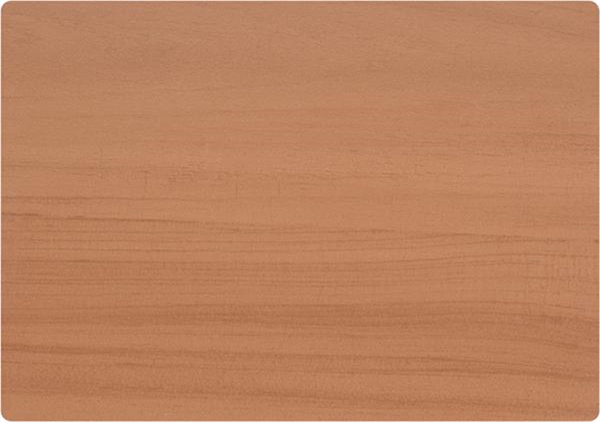

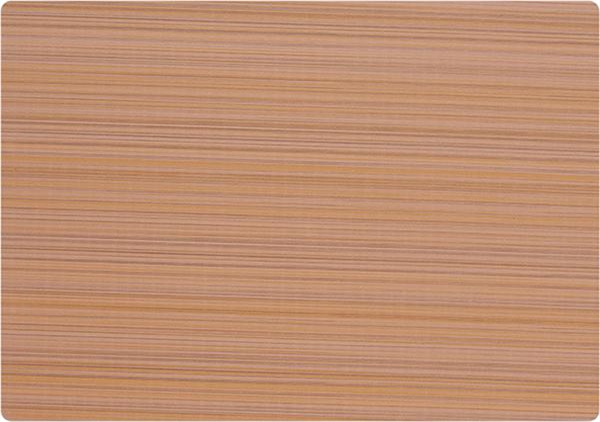

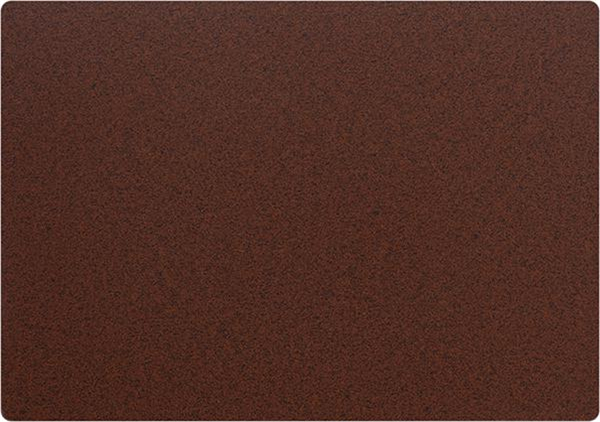

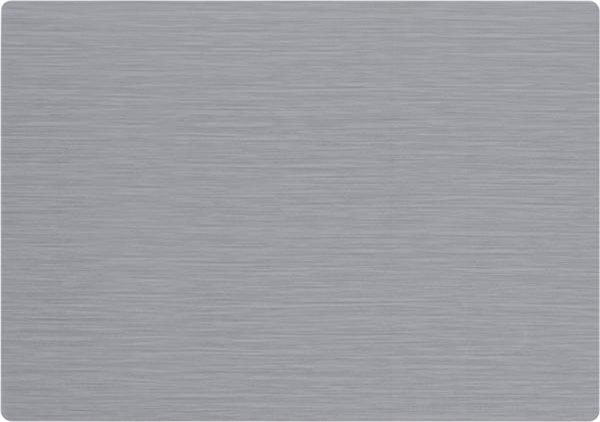

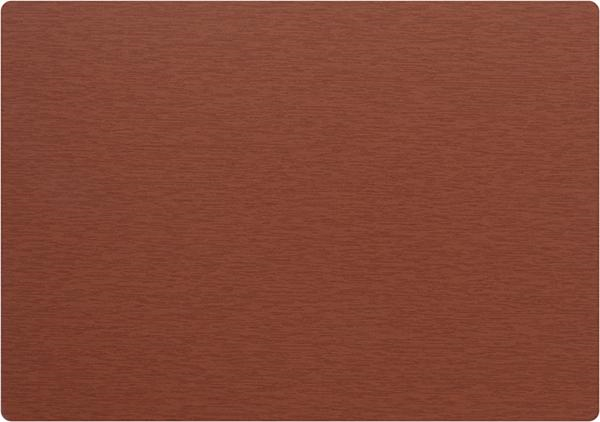

Colours/Order Samples

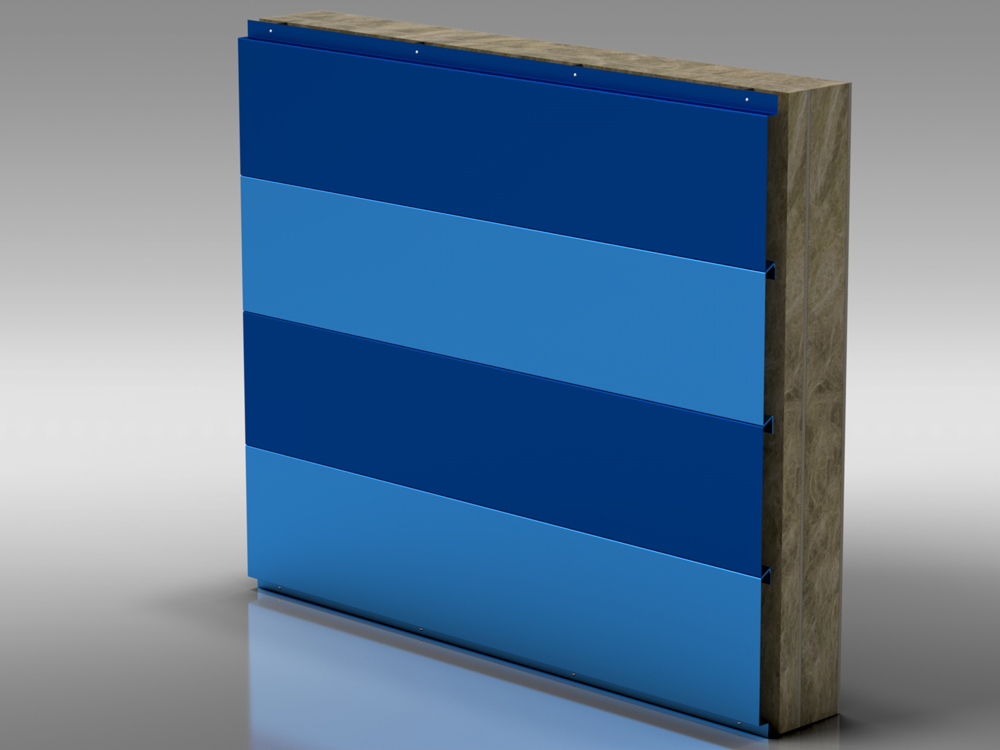

Fixing Systems

Flat Sheet

Futural flat sheet system is an uncomplicated, cost effective face fixed solution adopting the aesthetics of colour matched fixings.

Contact us for details >>Resources

Futural - A1 Report

Futural - 4000 Hours Salt Spray Report

Futural - 2000 Hours UV Acceleration Test Report

Futural - 4000 hours Humidity Resistance Report

Futural - 1000 Hours Acetic Spray Test Report

Futural - Coating Properties Test Report(AAMA 2605)

Futural - Aluminium Chemical Composition Report(EN 573-3)

Futural - Tensile Test Report(EN 485-2)

Futural - UKCA Declaration Of Product

Futural - UKCA Test Report(EN 14782)

Futural - UKCA Label

Looking To Use Futural

For Your

Next Project?